At the beginning of every VMI partnership, the companies must sit down to discuss the terms of their agreement. In addition to understanding the raw business specs such as fill rate or transaction costs, it�s also critical for you and your partner to understand each other�s business and big picture goals for the VMI partnership.

In the short-term, VMI is helpful because it removes the burden of having to juggle multiple inventory orders at once. The long-term picture is where VMI can have the greatest impact, however. VMI partnerships will simplify your supply chain and foster a long-term, trusting relationship with your partner.

Below is the first half of our list, 10 Things to Ask Your VMI Partner, to ensure you maximize your VMI relationship potential:

Do you clearly understand my goals?

It�s important to have a frank discussion upfront about the purpose of your VMI partnership. Are you just looking to reduce costs? Do you want to expand into new product markets? Your end goals may dictate the style of VMI you choose and how deeply you integrate the supplier into your business.

What about processes and pricing?

This is the time to discuss details such as fill rate, minimum order quantity, and costs. Ideally, your partner will already have good, established processes and pricing, and will tailor the VMI program to fit your specific business needs. Clarifying this information upfront means you can more easily plan and budget orders over time. VMI also streamlines billing to avoid the build-up of repetitive invoices and purchase orders.

What�s the level of technological integration?

Look for a provider who will heavily integrate technology into your custom VMI solution. Today, a lot of manual inventory counting, stocking, and weighing can be replaced with advanced software and automatic EDI alerts. Try to balance cost-efficiency with labor-efficiency.

Do you understand the market demand for my products?

Maybe your partner has worked with other industrial clients but not within your specific market. Maybe the market is changing. Whatever the case, let your partner know what to expect for typical market demand so both parties avoid becoming overwhelmed. Over time, your partner will learn the typical demand and plan inventory around it.

What is the relationship with the logistics provider?

If you use a third-party logistics provider, you should have a three-way partnership with plenty of open communication between you, them, and the vendor. VMI relationships benefit from the shared risk and investment in the venture. Therefore, all parties should work to foster each other�s success.

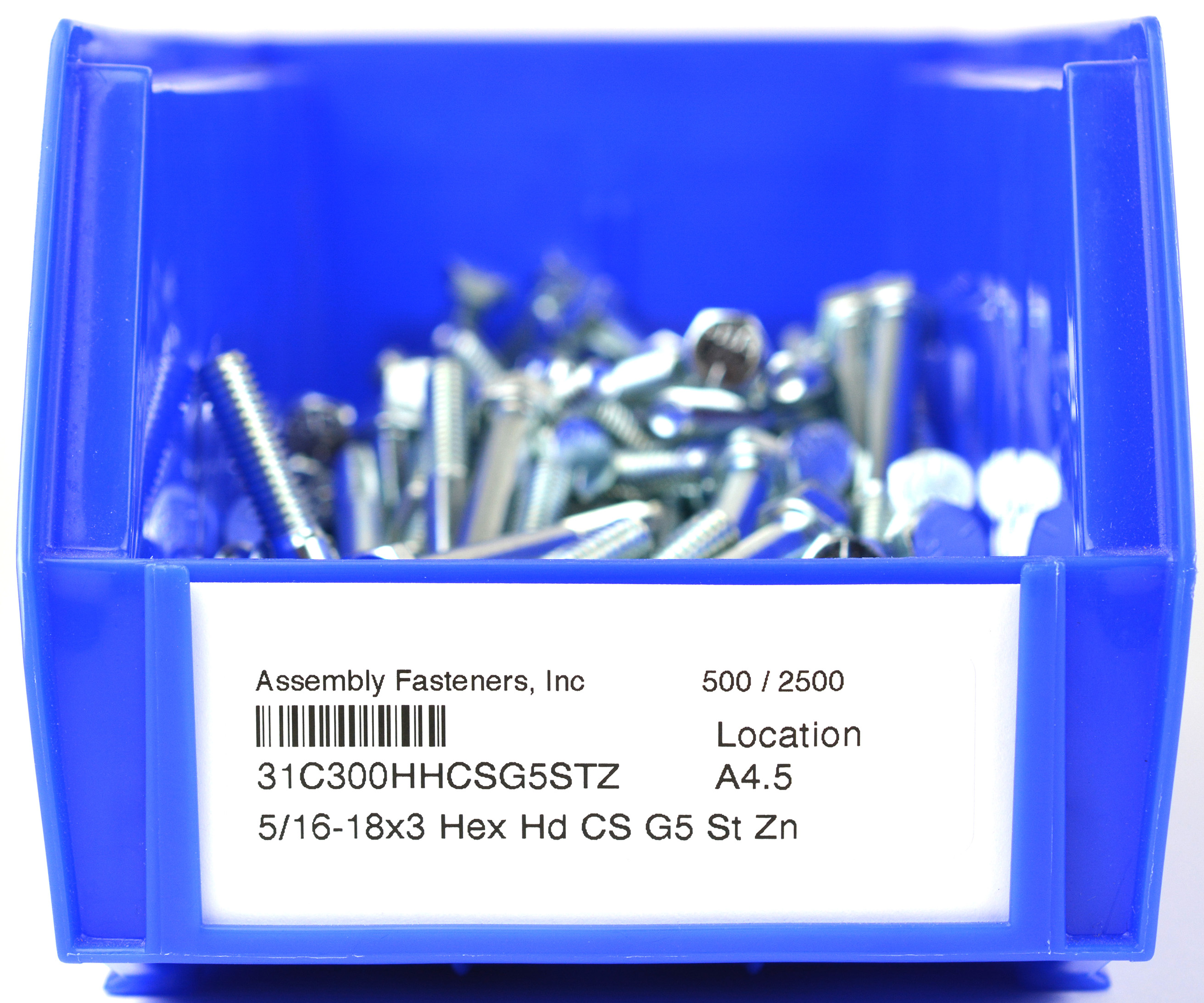

At Assembly Fasteners Inc (AFI) we have more than 30 years of experience and client success with our customizable VMI software solutions. To learn more about what VMI option is right for you, please download our eBook or visit the AFI website. Be sure to look out for the second half of our list 10 Things to Ask Your VMI Partner, coming soon.